Planning and Design

Building custom built-in cabinets is a rewarding DIY project that can dramatically enhance your home’s functionality and aesthetic appeal. Not only can you create storage solutions that perfectly fit your needs, but you can also personalize them with unique finishes and details.

Benefits of DIY Built-in Cabinets

DIY built-in cabinets offer several advantages over pre-made options, making them an attractive choice for homeowners.

- Customization: Built-in cabinets can be tailored to your exact specifications, ensuring they seamlessly integrate into your space and meet your specific storage needs. You have complete control over dimensions, materials, finishes, and hardware, creating a truly personalized solution.

- Cost Savings: While the initial investment in materials and tools may seem significant, DIY built-in cabinets can often be more cost-effective than buying pre-made options, especially for complex or unique designs.

- Increased Home Value: Well-designed and executed built-in cabinets can significantly increase your home’s value. They add a touch of luxury and functionality, making your space more desirable to potential buyers.

Measuring and Planning the Space

Accurate measurements are crucial for successful built-in cabinet construction. Here’s a step-by-step guide to ensure you get it right:

- Determine the Available Space: Measure the width, height, and depth of the area where you plan to install the cabinets. Consider any existing features, such as windows, doors, or electrical outlets, and factor them into your measurements.

- Sketch a Basic Layout: Draw a simple plan of the space, including all relevant dimensions and features. This will help you visualize different cabinet configurations and plan the placement of shelves, drawers, and other components.

- Consider Functionality: Think about how you will use the cabinets and what items you need to store. This will help you determine the size and type of cabinets needed, as well as the placement of shelves, drawers, and other features.

- Account for Cabinet Depth: Standard cabinet depths typically range from 12 inches to 24 inches. Consider the depth of your existing walls and the overall layout to ensure the cabinets fit comfortably within the space.

- Factor in Door Swing: If you are installing cabinets with doors, make sure you have enough space for them to open and close freely without obstructing any other features or furniture.

Designing Cabinet Configurations

The configuration of your built-in cabinets will depend on the room’s purpose and your individual needs. Here are some ideas for different room types:

Kitchen Cabinets

- Base Cabinets: Provide ample storage for cookware, appliances, and pantry items. Consider incorporating drawers for easy access to frequently used items and shelves for larger items.

- Wall Cabinets: Offer overhead storage for dishes, glassware, and other kitchen essentials. Consider using glass doors for display purposes or solid doors for a more streamlined look.

- Island Cabinets: Add additional storage and work space in the kitchen. They can be designed with a combination of drawers, shelves, and cabinets to accommodate various needs.

- Corner Cabinets: Maximize storage space in awkward corners. They can be designed with lazy Susans or pull-out shelves for easy access to items stored in the back.

Bathroom Cabinets

- Vanity Cabinets: Provide storage for toiletries, towels, and other bathroom essentials. Consider adding drawers for smaller items and shelves for larger items.

- Medicine Cabinets: Offer a dedicated space for medications and other personal care items. They can be recessed into the wall or mounted on the surface.

- Linen Cabinets: Provide storage for towels, linens, and other bathroom supplies. They can be built into a closet or placed in a separate area of the bathroom.

Bedroom Cabinets

- Closet Cabinets: Organize clothes, shoes, and other personal belongings. Consider incorporating shelves, drawers, hanging rods, and shoe racks to maximize storage space.

- Nightstand Cabinets: Provide bedside storage for books, lamps, and other essentials. They can be designed with drawers, shelves, or a combination of both.

- Dresser Cabinets: Offer storage for clothing, accessories, and other personal items. They can be built with drawers, shelves, or a combination of both.

Essential Tools and Materials, Diy built in cabinets

Before embarking on your DIY built-in cabinet project, ensure you have the necessary tools and materials. Here’s a checklist to get you started:

- Measuring Tape: Essential for accurate measurements of the space and cabinet components.

- Level: Ensures that cabinets are installed level and plumb for a professional finish.

- Circular Saw: Used to cut plywood and other materials for cabinet construction.

- Jig Saw: Used to cut intricate shapes and curves in plywood and other materials.

- Drill: Essential for drilling pilot holes and attaching hardware.

- Screwdriver: Used to drive screws and other fasteners.

- Clamps: Securely hold pieces of wood together during assembly.

- Safety Glasses: Protect your eyes from flying debris during cutting and drilling operations.

- Plywood: The primary material used for cabinet construction. Choose a high-quality plywood with a smooth finish for optimal results.

- Cabinet Doors and Drawers: Select doors and drawers that match your desired style and functionality.

- Hardware: Include hinges, drawer slides, knobs, and pulls to complete the cabinets.

- Paint or Stain: Choose a paint or stain that complements your existing décor and provides a durable finish.

Designing and Drafting a Plan

Creating a detailed plan for your built-in cabinets is essential for success. Here’s a step-by-step guide:

- Gather Measurements: Measure the available space accurately and record all dimensions on your plan.

- Sketch a Layout: Draw a basic layout of the cabinets, including their placement, size, and configuration.

- Determine Cabinet Components: Decide on the specific components for each cabinet, such as shelves, drawers, and doors.

- Choose Materials: Select the plywood and other materials you will use for construction, considering their strength, durability, and appearance.

- Create a Detailed Drawing: Draw a detailed plan of each cabinet, including all dimensions, cut lists, and hardware specifications.

- Prepare a Cut List: List all the pieces of plywood and other materials you need to cut, along with their exact dimensions.

- Create a Hardware List: List all the hardware you will need, such as hinges, drawer slides, knobs, and pulls.

Construction Techniques

The heart of any DIY built-in cabinet project lies in the construction techniques you employ. Choosing the right materials and mastering fundamental woodworking skills will ensure a sturdy and aesthetically pleasing final product. Let’s delve into the crucial aspects of building your dream cabinets.

Materials for Cabinet Construction

The choice of materials significantly impacts the durability, aesthetics, and cost of your cabinets. Here’s a breakdown of common options:

- Wood: Solid wood, like oak, maple, cherry, or walnut, offers classic beauty and longevity. It’s a natural material with distinct grain patterns, but it can be expensive and prone to warping or cracking if not properly treated.

- Plywood: This engineered wood is made of thin layers of veneer glued together with alternating grain directions. It’s more stable than solid wood, less expensive, and comes in various grades depending on the quality of the veneer. Plywood is a versatile option for cabinet construction.

- Medium-Density Fiberboard (MDF): This manufactured wood product is made from wood fibers compressed and bonded with resin. MDF is smooth, dense, and relatively inexpensive, making it suitable for cabinet doors and drawer fronts. However, it’s not as strong as solid wood or plywood and can be susceptible to moisture damage.

Cutting and Joining Wood

Precise cuts and strong joints are essential for sturdy cabinet construction. Here are some common techniques:

- Table Saw: Use a table saw for making accurate, straight cuts in wood. It’s ideal for cutting cabinet sides, shelves, and drawer fronts.

- Miter Saw: A miter saw is perfect for making angled cuts, such as for cabinet frames and molding. It offers precise cuts at various angles, ensuring tight joints.

- Router: A router can be used for shaping edges, creating decorative profiles, and cutting dadoes for shelf support. It’s a versatile tool for fine woodworking details.

- Joints:

Common Cabinet Joinery Methods:

| Method | Description | Illustration |

|---|---|---|

| Butt Joint: | A simple joint where two pieces of wood are butted together end-to-end. | [Image of a butt joint showing two pieces of wood joined together end-to-end.] |

| Dado Joint: | A groove cut into one piece of wood to receive the edge of another piece. | [Image of a dado joint showing a groove cut into one piece of wood to receive the edge of another piece.] |

| Rabbet Joint: | A rectangular groove cut into the edge of one piece of wood to receive the edge of another piece. | [Image of a rabbet joint showing a rectangular groove cut into the edge of one piece of wood to receive the edge of another piece.] |

| Mortise and Tenon Joint: | A strong joint where a tenon (projection) on one piece of wood fits into a mortise (hole) in another piece. | [Image of a mortise and tenon joint showing a tenon (projection) on one piece of wood fitting into a mortise (hole) in another piece.] |

Building Cabinet Doors

Cabinet doors can be constructed using various methods, each with its own advantages and disadvantages.

- Frame and Panel: This classic construction involves a frame made of wood strips that surrounds a flat panel. It’s a sturdy and elegant option, often used for traditional cabinets.

- Slab Doors: Slab doors are made from a single piece of wood or plywood. They’re simpler to build but can be less durable than frame and panel doors.

- Mitered Doors: Mitered doors are made from multiple pieces of wood joined at angled cuts. They can create intricate designs and are often used for contemporary cabinets.

Building Cabinet Drawers

Cabinet drawers are typically constructed using a box-like design with sides, a bottom, and a front.

- Drawer Box: The drawer box is the main structure of the drawer. It’s typically made from plywood or MDF and assembled using dado joints or rabbet joints.

- Drawer Front: The drawer front is the visible part of the drawer. It can be made from various materials, including wood, plywood, or MDF. It’s often attached to the drawer box using a dado joint or a rabbet joint.

- Drawer Slides: Drawer slides are the mechanism that allows the drawer to move in and out of the cabinet. There are various types of drawer slides, including side-mount, full-extension, and under-mount slides.

Installing Hinges, Drawer Slides, and Other Hardware

Installing hinges, drawer slides, and other hardware requires precision and care to ensure smooth operation and a professional finish.

- Hinges: Hinges are used to attach cabinet doors to the cabinet frame. They come in various types, including overlay, inset, and concealed hinges. Choose the appropriate type based on the style and design of your cabinets.

- Drawer Slides: Drawer slides are installed on the sides of the drawer box and the cabinet frame. They allow the drawer to move smoothly in and out of the cabinet. Make sure to align the slides correctly and install them securely.

- Other Hardware: Other hardware components, such as knobs, pulls, and handles, add functionality and aesthetics to your cabinets. Choose hardware that complements the style and design of your cabinets.

Finishing and Installation: Diy Built In Cabinets

The final stage of your built-in cabinet project involves adding the finishing touches and installing them securely. This step is crucial for both aesthetics and functionality, ensuring your cabinets look great and last for years to come.

Finishing Options

Choosing the right finish can dramatically impact the overall look and feel of your cabinets. Here’s a breakdown of popular options:

- Painting: Painting is a versatile and cost-effective option. It offers a wide range of colors and finishes, from high-gloss to matte, allowing you to match your existing decor or create a bold statement. Prepare the cabinet surfaces by sanding them smooth and applying a primer for optimal adhesion. Choose a high-quality paint designed for cabinets, and apply multiple thin coats for a smooth, even finish.

- Staining: Staining brings out the natural beauty of wood, enhancing its grain patterns and adding depth. It’s a great choice for cabinets made from hardwoods like oak, maple, or cherry. Before staining, ensure the wood is clean and free of dust or debris. Apply a pre-stain conditioner to even out the absorption of the stain. Choose a stain color that complements your room’s aesthetic, and apply it evenly using a brush or cloth.

- Laminating: Laminate is a durable and low-maintenance option that offers a wide variety of colors, patterns, and textures. It’s a great choice for high-traffic areas or if you want a more modern look. Laminate sheets are available in different thicknesses and can be applied to cabinet surfaces using contact cement or a heat-activated adhesive. Make sure to cut the laminate precisely to fit your cabinets and apply it with even pressure for a seamless finish.

Preparing and Applying Finishes

Proper preparation is essential for a flawless finish. Here’s a step-by-step guide:

- Clean the surface: Remove dust, debris, and any existing coatings with a damp cloth and mild detergent. Allow the surfaces to dry completely before proceeding.

- Sand the surface: Use sandpaper to smooth out any imperfections and create a uniform surface for the finish to adhere to. Start with coarse grit sandpaper and gradually move to finer grits for a smoother finish.

- Prime the surface: A primer helps the finish adhere better and provides a uniform base for the final coat. Choose a primer specifically designed for the type of finish you’re using.

- Apply the finish: Use a high-quality brush, roller, or spray gun to apply the finish evenly. Follow the manufacturer’s instructions for drying time and multiple coats.

Installing Built-in Cabinets

Installing built-in cabinets requires careful planning and execution. Here’s a breakdown of the process:

- Measure and mark: Accurately measure the space where the cabinets will be installed and mark the wall and floor using a level. Ensure the measurements are precise to avoid any gaps or misalignments.

- Secure to the wall: Use appropriate fasteners, such as screws or anchors, to attach the cabinets to the wall. Ensure the fasteners are long enough to reach studs or secure to the wall structure for maximum stability.

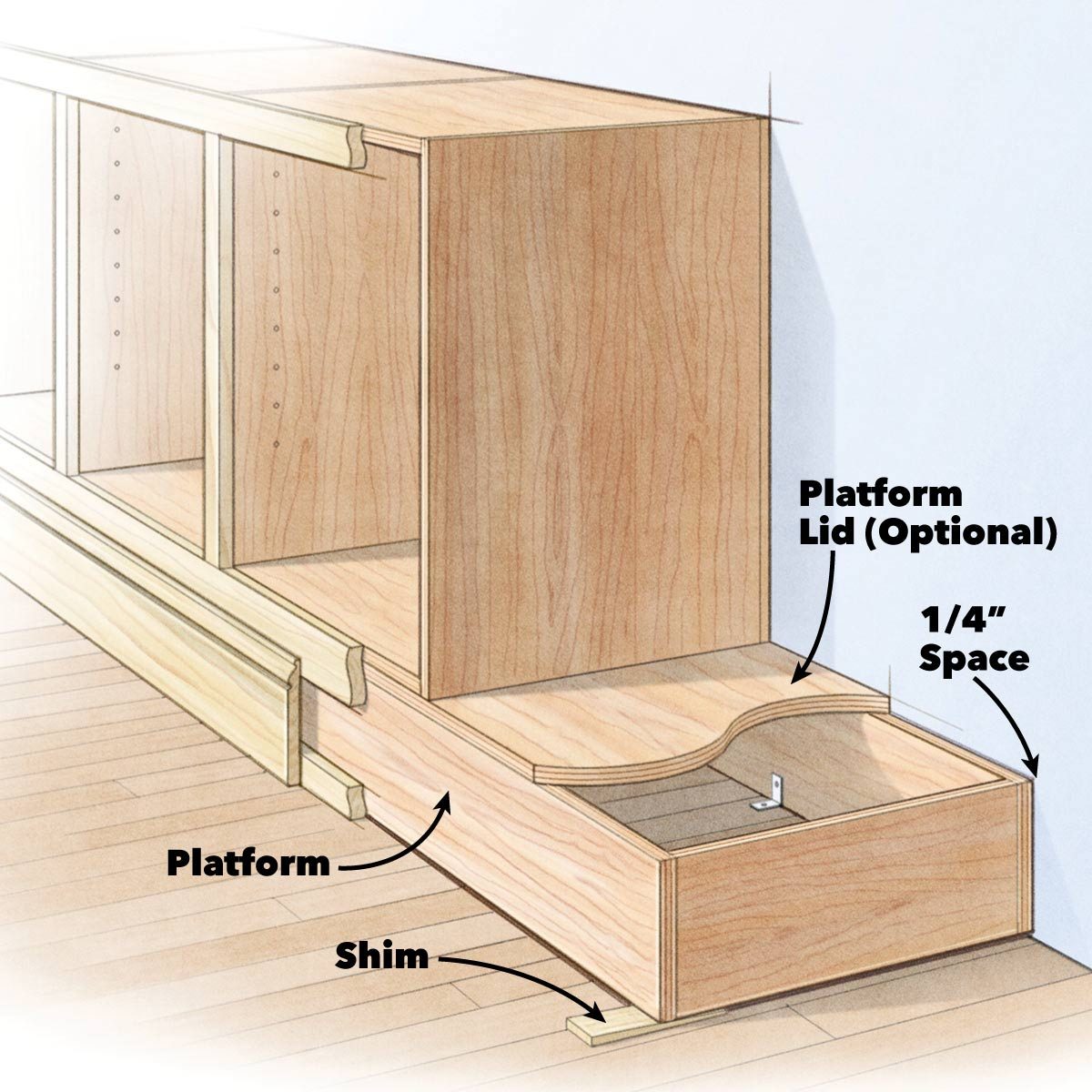

- Level and adjust: Use a level to ensure the cabinets are perfectly horizontal and plumb. Make adjustments as needed using shims or spacers.

- Attach to the floor: If necessary, secure the base of the cabinets to the floor using screws or anchors. This helps prevent movement and ensures stability.

Integrating Cabinets with Existing Features

For a seamless look, it’s essential to integrate your built-in cabinets with the existing room features. Consider the following:

- Match the trim: Use the same trim as the existing moldings and baseboards to create a cohesive look. This can be achieved by using matching paint or stain.

- Consider the lighting: Integrate the cabinets with the existing lighting scheme. Add under-cabinet lighting or recessed lighting to highlight the cabinets and provide functional illumination.

- Incorporate the existing features: If the room has a fireplace or other architectural elements, design the cabinets to complement them. This creates a harmonious and visually appealing design.

Safety Precautions

Safety is paramount during the installation process. Here’s a checklist of precautions to take:

- Use appropriate safety gear: Wear safety glasses, gloves, and a dust mask to protect yourself from dust, debris, and chemicals.

- Use a ladder safely: Ensure the ladder is stable and placed on a level surface. Never overextend yourself or reach too far while on a ladder.

- Be aware of electrical wires: Before drilling or cutting into the walls, use a stud finder to locate electrical wires and avoid damaging them.

- Follow manufacturer’s instructions: Always follow the manufacturer’s instructions for the tools, materials, and finishes you’re using.

Diy built in cabinets – DIY built-in cabinets offer a fantastic way to maximize storage and create a sleek, custom look in your kitchen. If you’re aiming for a dramatic and modern feel, consider incorporating black cabinets, which can be a stunning backdrop for a variety of countertop materials.

For an even bolder statement, pair your black cabinets with black appliances, as seen in this inspiring design guide black cabinets with black appliances. Whether you’re opting for a sleek minimalist look or a more industrial vibe, black cabinets with black appliances can truly transform your kitchen.

With careful planning and a bit of effort, your DIY built-in cabinets can become the centerpiece of your dream kitchen.

DIY built-in cabinets can transform a room, adding storage and a touch of custom design. While laminate is a popular choice for its durability and affordability, you might wonder if you can stain it to achieve a desired look. The answer is a bit nuanced, as the process depends on the type of laminate.

If you’re considering staining, can you stain laminate cabinets provides some helpful insights. Regardless of your staining decision, remember that built-in cabinets offer a unique way to personalize your space.